Global Monitor (July 2008)

Thirty years after the U.S. government began assessing if a remote ridge in the Mojave Desert 90 miles northwest of Las Vegas, Nev., was suitable for the nation’s first permanent deep geologic nuclear waste repository, the Department of Energy (DOE) has formally filed an application with the Nuclear Regulatory Commission (NRC) for a license to proceed with construction.

The 17-volume, 8,600-page application that the NRC received by truck on June 3 details the DOE’s plan to safely isolate spent nuclear fuel and high-level radioactive waste in tunnels deep underground at Yucca Mountain. The submission marks an apex in the Yucca Mountain saga: For the first time since Congress enacted the Nuclear Waste Policy Act (NWPA) in 1982, the focus will shift away from the DOE and to the NRC.

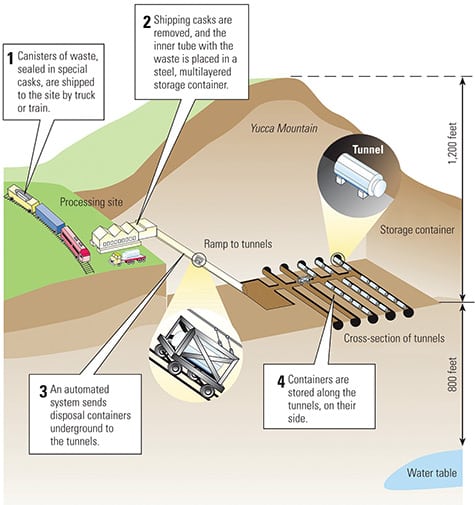

Now, the NRC must review the DOE’s plan and decide whether the repository can safely contain 77,000 tons of high-level waste, including 57,000 tons of commercial spent fuel that is being currently stored at 121 temporary locations in 39 states across the nation (Figure 1).

1. Moving closer to construction. The DOE filed a formal application with the NRC for a license to begin construction of a high-level nuclear waste repository deep within Yucca Mountain in Nevada. The application defines how the facility can safely store the waste for at least 10,000 years. Source: DOE

The regulatory body will accomplish this in two phases. First, it will conduct a technical licensing review to assess the technical merits of the repository design and decide whether to permit construction. This phase will involve more than 100 employees with expertise in several scientific disciplines, including geochemistry, hydrology, climatology, structural geology, volcanology, and seismology. The second phase involves hearing challenges concerning the technical and legal aspects of the DOE’s application before the NRC’s Atomic Safety and Licensing Boards.

As long as the NRC deems the DOE’s application sufficiently complete, it will make a decision based on technical merits in about three years. If the construction license is approved, then the DOE would be required to request a license to receive and possess high-level waste at Yucca Mountain, and this application would go through another round of NRC reviews and hearings.

The DOE, which has already spent $9 billion on the project, anticipates that the “receive and possess” license will be awarded in March 2013. If all goes well, the best achievable date to begin operations is March 2017.

Driven now more than ever by mounting interest in a U.S. nuclear power revival, the Yucca Mountain repository may just come to fruition—and if does, it will be one of the first in the world. Yucca Mountain, which lies on federal land, is a rare but optimum location for a repository, the DOE says, because it brings together natural barriers and design elements.

Similar long-term solutions to store high-level nuclear waste are being sought around the world. Presentations at a 2006 international conference on the management of spent fuel from nuclear power reactors in Vienna organized by the International Atomic Energy Agency revealed a broad international consensus that deep-geological disposal was seen as the most viable long-term solution for the disposition of highly radioactive nuclear waste. In addition to the U.S., Belgium, Canada, Finland, France, Germany, Sweden, Switzerland, and the UK have all performed detailed studies, or characterizations, drilling numerous boreholes and exploratory shafts and ramps in underground research laboratories. Besides Yucca Mountain, among the repositories planned that may soon be realized are ones in Sweden, Finland, and Canada.

Sweden has operated an interim repository for spent fuel since 1985 at Oskashamn and recently expanded it to accommodate fuel from the country’s 10 reactors. The used fuel, which is being stored underwater in an underground rock cavern for some 40 to 50 years, will be encapsulated in copper and stainless steel canisters for final emplacement packed with bentonite clay in 1,640-foot granite repository. To date, two potential sites have been identified for this final repository, and both will now undergo more detailed site investigation.

Meanwhile, the Canadian government is reviewing Ontario Power Generation’s (OPG’s) proposal that a low- and intermediate-level nuclear waste repository be built on the Bruce Nuclear Site in Ontario. If the government approves the license, OPG could begin using the deep geologic repository by 2025.

Among the challenges the DOE faces in implementing the repository at Yucca Mountain is a lack of public support. The DOE’s formal application to the NRC in June sparked blistering critiques from Nevada officials and resident groups. As well as filing multiple lawsuits against the DOE in the Washington, D.C., Court of Appeals, Nevada governor Jim Gibbons has banded together the state’s congressional delegation to oppose the “dump,” saying that it poses too many potential problems, including “groundwater contamination,” transportation of radioactive waste, and the federal government’s “encroachment on state rights.” And House Majority Leader Sen. Harry Reid (D-Nev.), a long-time opponent of the project, recently led a congressional funding slash for the project.

In contrast, the development of deep geologic repositories is lauded in some parts of the world, where it is seen as a permanent solution to a long-term problem. In Sweden, for example, more than 75% of residents who live around the two identified potential sites supported having the final repository in their locality, an independent April 2008 poll found. And in Finland, where (as in the U.S.) nuclear waste management is governed by a statute that requires permanent disposition, an approved plan to store spent fuel from the country’s four reactors is already in place—and has national and local support.

CPV cells get cooling chips from IBM

A new solar energy system invented by IBM researchers could render concentrator photovoltaic (CPV) technology cost-effective and more efficient. The computer technology company has combined innovations from its R&D in cooling computer chips with a large magnifying glass and a tiny solar cell—and it has so far generated power of a density five times that of CPV cells used in typical solar farms.

The scientists used a large magnifying glass to concentrate about 200 sun systems onto a 0.4-square-inch solar cell into 2,300 sun systems (“one sun” is a measurement equal to the solar power incident at noon on a clear summer day). The team then used a liquid metal cooling interface used in microprocessor technology to cool the intense heat of about 2,912F—enough to melt stainless steel, as researchers experienced firsthand in their experiments—to about 185F. The device ultimately captured a record 230 W on the solar cell and then converted it into 70 W of electric power, IBM said (Figure 2).

2. Big Blue goes green. IBM researchers have coupled a liquid metal cooling technology developed for the microprocessor industry with a large magnifying glass and a tiny solar cell to render concentrator photovoltaics more effective. Courtesy: IBM

IBM had earlier developed the liquid metal cooling technology to cool high-power computer chips. It consists of a very thin layer of a liquid metal made of a gallium and indium compound that is applied between the chip and a cooling block. Such layers, called thermal interface layers, transfer heat from the chip to the cooling block so that the chip temperature can be kept low.

IBM said that if it can overcome additional challenges to commercialize the project, the technology could lower the number of photovoltaic cells in a solar farm by concentrating more light onto each cell using larger lenses—and that this could ultimately make CPV technology more cost-efficient.

Though concentrator-based photovoltaics technologies have been around since the 1970s, they have received renewed interest recently.With very high concentrations, they have the potential to offer the lowest-cost solar electricity for large-scale power generation—provided the temperature of the cells can be kept low and that cheap and efficient optics can be developed for concentrating the light to high levels.

IBM is currently exploring four main areas of photovoltaic research: using current technologies to develop cheaper and more efficient silicon solar cells; developing new solution-processed thin-film photovoltaic devices; concentrator photovoltaics; and future generation photovoltaic architectures based upon nanostructures such as semiconductor quantum dots and nanowires.

StatoilHydro to pilot test first offshore floating wind turbine

If an $80 million plan by Norwegian oil company StatoilHydro to test a full-scale floating deepwater wind turbine off Norway’s coast next year is successful, the wind industry could see renewed installation frenzy.

StatoilHydro’s 2.3-MW wind turbine will be built by Siemens atop a “Spar-buoy,” which is based on the design of production platforms and offshore loading buoys. The rotor blades on the floating wind turbine will have a diameter of 262 feet, and the nacelle will tower 213 feet above the waves (Figure 3). The floatation element, built by Technip, will have a draft of 1,076 feet below the sea surface, and it will be moored to the seabed using three anchor points. From tests that StatoilHydro conducted with a 10-foot-high model in a wave simulator in Trondheim, Siemens and StatoilHydro have determined that the turbine can be located in waters with depths of 394 feet to 2,297 feet.

3. Come wind or high water. Norwegian company StatoilHydro will test the world’s first floating deepwater wind turbine in 2009 off Norway’s coast. The device’s rotor blades will have a diameter of 262 feet, and the nacelle will tower 213 feet above the waves. Courtesy: StatoilHydro

The pilot project will be assembled in Åmøyfjorden, near Stavanger, and is to be located some 6.2 miles offshore Karmøy in southeast Norway. Siemens, which has entered into a technology development agreement with StatoilHydro on the project, will ensure that the turbines function optimally during the two-year test, even in large waves.

The goal of the pilot is to qualify the technology and reduce costs to a level that will enable floating wind turbines to compete with other energy sources, said Alexandra Bech Gjørv, head of New Energy at StatoilHydro.

“Floating wind power is not mature technology yet, and the road to commercialisation and large scale development is long. An important aspect of the project is therefore research and development,” she said. “If we are to succeed, we will need to cooperate closely with the authorities. As with other technologies for renewable energy, floating wind power will be dependent on incentive schemes to be viable.”

U.S. rivers next massive power source?

Major U.S. rivers could soon feed several underwater turbine arrays with their massive power potential if some of the more than 100 projects that a Houston-based alternative energy firm has filed with the Federal Energy Regulatory Commission (FERC) are approved.

Free Flow Power Corp. (FFP) has developed a hydrokinetic turbine generator system that extracts energy from moving water without requiring the construction of new dams or diversion. The company wants to submerge the system, which can be installed in an array of different configurations to suit site conditions, in the Mississippi, Missouri, Ohio, Niagara, and Detroit Rivers (Figure 4).

4. River current. Free Flow Power Corp., a hydrokinetic energy firm, has filed more than 100 projects with the Federal Energy Regulatory Commission to install its turbine generation system in major U.S. rivers. The turbines can be arranged in arrays to suit site conditions. Courtesy: Free Flow Power Corp.

FFP’s turbine uses a rim-mounted, permanent magnet, direct-drive generator with front and rear diffusers and a moving rotor to maximize efficiency. So far, the company’s prototype has undergone land testing and subjection to Alden Labs’ newest test flume, which mimics the flows found in river, tidal, and ocean current environments. Its two-meter version, which is expected to generate 10 kW in flows of 4.5 miles per hour is currently being deployed in a Massachusetts canal test.

Meanwhile, FFP is planning big: In the Mississippi River it plans to place about 150 such generators in a linked system on the riverbed and transmit the hydropower through an onshore converter. And it reportedly proposed installing 875 submerged turbines along a corridor in the Niagara River. Each of the U.S. projects planned would consist of between 900 and 5,000 turbines configured in a series of matrices, the company said on its web site.

Before it can begin mass-producing power, however, the company must garner regulatory approval for a majority of its projects, a process that could take up to five years. Although FERC recognizes that hydrokinetic technologies, if fully developed, could double the amount of hydropower production in the U.S.—bringing it from under 10% to 20% of the national electrical supply—regulatory hurdles continue to be complex.

Siemens delivers 500-MW gasifiers

Siemens Energy has delivered the first two of five massive coal gasifiers—each with a thermal capacity of 500 MW—to Shenua Ningxia Coal Industry Group Co.’s coal-to-polypropylene plant (SNCG) in China.

The gasifiers, which are 59 feet long with an inside diameter of about 10 feet, weigh 220 tons and are capable of gasifying up to 2,000 tons of coal daily. Gasification takes place in a cylindrical reaction chamber at temperatures above the coal-ash fusion temperature. Finely ground fuel that is introduced with a mixture of oxygen, and steam via a burner at the head of the reactor is converted within a few seconds into raw syngas consisting mainly of carbon monoxide, hydrogen, carbon dioxide, and water (Figure 5).

5. Coal gasifier. As recently delivered to a coal-to-polypropylene plant in China, Siemens Energy’s newest 500-MW gasifier is capable of gasifying 2,000 tons of coal daily. Finely ground fuel introduced via a burner at the head of the reactor is instantly converted into raw syngas. Solidified clinker granules can be removed via a material lock at the foot of the quenching chamber. Courtesy: Siemens

Though SNCG will use the five-gasifier plant to produce about 19 million cubic feet of syngas for conversion in downstream processes to polypropylene plastic, the technology can effectively be used for power generation in integrated gasification combined-cycle plants, Siemens said.

Siemens produced the gasifiers in about 18 months, beginning work soon after it acquired the technology for the gasification of fossil raw materials from the Swiss company Sustec Holding AG in 2006.

Algae: A green solution

To stay within shrinking federal and state carbon emission allowances, companies in the U.S. and around the world are scrambling to take up innovative solutions and clean up or cut down carbon dioxide emissions. Amid ongoing gasification tests and carbon sequestration experiments, Massachusetts-based GreenFuel Technologies Corp. has been quietly conducting studies with several companies at their coal-fired plants to develop high-yield algae farm technologies. Its mission: to profitably recycle industrial carbon dioxide and produce feed, food, and fuel ingredients.

A few years ago, the concept would have been dismissed as ineffective, even though for some time now, algae have been used in wastewater treatment facilities to sop up toxic chemicals and at farms to capture fertilizers in runoff. As autotrophic organisms, algae can produce their own food from inorganic substances such as carbon dioxide and inorganic nitrogen. They are the fastest growing plants in the world, and they do not need clean water or land. And from several studies, GreenFuel has found that, as well as recycling atmospheric carbon dioxide, the entire biomass produced from algae can be used and that oil retrieved from the organism could be used as a renewable biofuel.

A company that began operations in 2001, GreenFuel has so far conducted successful pilot installations to recycle carbon dioxide at several plants, including the Redhawk and Four Corners plants owned by Arizona Public Service (APS), NRG’s Dunkirk plant in New York and its Big Cajun plant in Louisiana, and a Sunflower Electric plant in Kansas.

APS and GreenFuel partnered in 2005 and recycled 80% of daytime carbon dioxide emissions from APS’ 1,040-MW gas-fired Redhawk Power Station using an algae bioreactor. The contraption was simple: Carbon dioxide emissions coming out of the stack were directed through specially designed pipes and into specialized containers holding hungry algae. In the presence of sunlight, the algae consumed the carbon dioxide (Figure 6). GreenFuel then converted the carbon-rich algal biomass into transportation-grade biodiesel and ethanol.

6. Hungry critters. An algae bioreactor system connected directly to the stack of APS’ 1,040-MW Redhawk Power Station successfully recycled greenhouse gases into renewable biofuels in 2006. Courtesy: APS

In 2007, APS announced that the team would attempt to replicate its success using emissions from APS’ coal-burning Four Corners Power Plant. Earlier that year, GreenFuel had teamed up with NRG to install the company’s Emissions-to-Biofuels process to capture NRG’s flue gas carbon dioxide. GreenFuel indicated on its web site that both projects were successful, although it did not give any details.

So will the use of algae bioreactors catch on as a commercial solution to the complex carbon dioxide emissions problem? “GreenFuel’s extensive economic analyses and cost estimates show that algae can be grown economically as a commercial product. Many estimates claiming that algae are not commercially viable use outdated economics for product values that are no longer valid, or assume use of initial generations of experimental technology that have since been upgraded,” the company says on its web site. “GreenFuel believes that ecological and energy issues are complicated and will require a variety of solutions—of which algae will be one.”

POWER digest

News items of interest to power industry professionals.

Detroit Edison selects GE Hitachi Nuclear Energy’s ESBWR reactor design. Detroit Edison (DTE) announced in mid-June that it has selected GE Hitachi Nuclear Energy’s next-generation economic simplified boiling water reactor (ESBWR) design for a potential new unit at its existing Fermi 2 Power Plant site on the shore of Lake Erie, 35 miles south of Detroit. (POWER selected Fermi 2 as one of its Top Plants in the remodeled nuclear plant category in 2007.)

DTE had previously notified the U.S. Nuclear Regulatory Commission (NRC) of its plans to choose the 1,520-MW ESBWR when it submits a combined operating license application (COLA) to the agency in September. Under a recent agreement, GE Hitachi Nuclear Energy (GEH) will provide DTE technical support for its COLA.

DTE joins Dominion Energy’s North Anna, Va., site and Entergy’s (NuStart) Grand Gulf, Miss., site with COL applications on file with the NRC. Entergy’s River Bend, La., and Exelon’s two-unit greenfield project in Victoria County, Texas, are expected to file by year’s end.

DTE is considering building an ESBWR plant to help address the recommendations of Michigan’s 21st Century Energy Plan, which makes clear the state’s need for additional plants over the next two decades to ensure sufficient generating capacity.

“By preparing and submitting a COLA now for a potential ESBWR, we are acting in the best interests of our customers by making sure we are doing everything we can to meet the state’s future energy, environmental and economic needs,” said DTE Chairman and CEO Anthony Earley Jr.

“However,” Earley said, “before we can commit to building a new plant, the Michigan legislature must make changes to the state’s current regulatory structure. A package of bills that would make some of the necessary changes is pending, and we urge the legislature to adopt those measures so that we move forward with this investment in Michigan’s long-term energy future.”

Though submitting a COLA does not commit DTE to build the reactor project, it is necessary for utilities to submit COLAs by Dec. 31, 2008, to be eligible for federal financial incentives included in the Energy Policy Act of 2005, Earley noted.

The ESBWR plant project could create up to 3,000 temporary construction jobs and up to 700 permanent engineering and other support positions in the state.

Germany cuts solar support. Germany will cut support for the country’s solar energy program—the largest in the world—by 8% in 2009 and 2010 and by 9% in 2011. The cuts were necessary to redirect financial help to other types of renewable energy such as wind and biomass installations, the government said on May 29.

The cuts would affect rooftop panels, which provide a majority of Germany’s solar energy. The decline in support for bigger installations on open fields was larger, starting at 10% next year and falling to 7% and 8% in the following years. The cuts reportedly fell short of those demanded by some German conservatives, who had requested a funding slash of 30% for rooftop solar panels.

As a result of a renewable energy law passed in 2000, Germany has seen a solar energy boom. More than half the world’s photovoltaic energy is produced in Germany, much of it from 300,000 systems on rooftops. Industry sources said that the cuts were bearable because solar energy produced in Germany by 2015 would compete with electricity generated from fossil fuels.

Germany also holds the record for the world’s highest installed wind capacity.

Mesa Power places world’s largest single-site wind turbine purchase order. Mesa Power LLP, a company created by legendary energy executive T. Boone Pickens, has placed an order with General Electric to purchase 667 wind turbines capable of generating 1,000 MW of electricity.

The agreement represents the first phase of the four-phase Pampa Wind Project that will become the world’s largest wind energy project, with a capacity of more than 4,000 MW of electricity. When all phases of the project are completed as projected in 2014, the wind farm will be five times as big as the current largest wind power project in the U.S., with a capacity of 736 MW.

Pickens said he expects that the first phase of the project will cost about $2 billion and that electricity from it will be on-line by early 2011. When complete, the Pampa Wind Project will cover some 400,000 acres in the Texas Panhandle. Pickens said extensive testing has shown that the project area has some of the best wind in the nation.

GE is to deliver the 1.5-MW wind turbines (among the most widely used turbines in their class) in 2010 and 2011.

In August of 2007, Mesa Power filed documents with the Electric Reliability Council of Texas (ERCOT) to add the 4,000 MW of wind-generated electricity to the power grid in Texas. ERCOT, which operates as part of the Public Utility Commission of Texas, manages the state’s power grid. Mesa Power has nominated its wind turbine output to be delivered by the state’s Competitive Renewable Energy Zones (CREZ) transmission lines. The CREZ transmission lines will benefit Texas electricity users by delivering cost-effective and reliable electricity generated by renewable energy power projects.

Pickens envisions that large-scale renewable energy projects like his Pampa Wind Project will permit the U.S. to become less dependent on foreign oil. Large-scale renewable energy projects such as this are difficult to execute because they rely upon the federal Production Tax Credit (PTC), which provides incentives for developing renewable energy. However, large-scale renewable energy projects require commitments years in advance, while Congress has only extended the PTC one or two years at a time.

Mesa Power is hopeful that the Pampa Wind Project will qualify for the PTC in 2010 and 2011, when the project will begin commercial operation. “I believe that Congress will recognize that it is critical not only to this project, but to renewable energy in this country, that they enact a long-term extension of the Production Tax Credits,” Pickens said.

DOE formally ends FutureGen participation. Energy Secretary Samuel Bodman in mid-June sent a letter to companies involved in the FutureGen Alliance formally withdrawing the Department of Energy’s participation in a $1.5 billion project to build a unique, near-zero-emissions coal-fired power plant in central Illinois.

The DOE’s withdrawal was expected. On January 29, 2008, barely a month after the FutureGen Alliance had announced its long-awaited decision about the location of demonstration plant, the DOE had announced it would pull its funding for the project—mostly due to higher-than-expected costs. (See the first stories in Global Monitor in the February and March 2008 issues of POWER.)

Secretary Bodman had then stated that the FutureGen project would be restructured and that the DOE would “equip multiple new clean-coal power plants with advanced CCS technology, instead of one demonstration plant.”

According to the Associated Press, the DOE now plans to start over while continuing its efforts to pay for several clean-coal projects around the country. The agency is to seek proposals for those projects in the coming weeks, a spokesperson told the AP.

GE-Hitachi Nuclear receives NRC license amendment for Global Laser Enrichment test loop. Global Laser Enrichment (GLE), a subsidiary of GE-Hitachi Nuclear Energy (GEH), was notified May 12 that the U.S. Nuclear Regulatory Commission had approved a license amendment request to operate a test loop for GLE’s next-generation laser enrichment technology.

GLE will use information gained from the test loop to make a final decision on the construction of a commercial facility as early as the beginning of 2009. GLE is currently preparing an NRC license application to build and operate the commercial plant.

The test loop is being built in the nuclear fuel manufacturing facility operated by Global Nuclear Fuel-Americas LLC (GNF-A), which is colocated at GEH’s nuclear energy headquarters site in Wilmington, N.C. At GEH’s request, GNF-A applied to the NRC to amend its nuclear materials facility license so that GLE can perform confirmation testing of the laser enrichment technology.

With facility construction nearly complete, GLE anticipates beginning installation of test loop equipment—such as lasers, gas-handling equipment, and auxiliary systems—in the near future. A primary objective of the test loop is to advance the design of the commercial facility building, equipment, and processes.This involves designing components for the commercial production facility itself, as well as ascertaining the specifications and range of operating parameters needed for equipment to be used in commercial production. As part of this process, UF6 will be enriched in small amounts and then blended back to natural UF6.

GEH has exclusive rights to develop, commercialize, and launch this third-generation uranium enrichment technology on a global basis. Commercial facility licensing activities are under way to support a projected start-up date of 2012. The GLE commercial facility would have a target capacity of between 3.5 and 6 million separative work units.

GEH announced April 30 that it had selected its Wilmington site to host the potential full-scale enrichment facility if it formally decides to proceed with construction of the plant.

Mitsubishi to supply natural gas turbine to E4 Group in Russia. Mitsubishi Heavy Industries Ltd. (MHI) will supply the E4 Group—a plant engineering, procurement, and construction company in Russia—with an M701F gas turbine to be used at a new power generation plant of OAO UGK TGK-8 (TGK-8), a regional power producer.

TGK-8 plans to build a 400-MW natural gas-fired turbine combined-cycle (GTCC) power generation plant in the Krasnodar region on the Black Sea coast. The MHI-supplied gas turbine will be the key component of the GTCC plant and is expected to contribute significantly to alleviating the tight local electricity situation.

This will be MHI’s first gas turbine order from Russia.

Alstom to supply wind turbines to Iberdrola. Alstom’s wind subsidiary Ecotecnia announced in May that it had entered into a $466.68 million frame agreement to supply wind turbines with a total capacity of 300 MW to Iberdrola Renewables, marking Alstom’s first large agreement of this kind in wind energy since it acquired Ecotecnia in November 2007. Under the agreement, Alstom will supply Iberdrola Renewables with the turbine models Eco 74, Eco 80, and Eco 80 2.0 over a period of four years.

Eskom selects Black & Veatch to provide project services for new power plant. Black & Veatch has been selected by Eskom, South Africa’s state-owned electric utility, to provide project management and engineering services for a 4,800-MW power generation facility being constructed in South Africa.

Black & Veatch will assist with engineering services and supervising construction of six 800-MW units that will constitute Project Bravo, a 4,800-MW supercritical coal-fired generation facility about 120 miles east of Johannesburg. The units’ design will feature flue gas desulfurization.

Project Bravo is scheduled to be completed in stages, with the first unit coming on-line in 2012 and the final unit in 2015. Project Bravo work for Eskom, the world’s 11th-largest electric utility, is now under way and will ultimately provide needed power for South Africa’s growing economy. The country’s electric supplies are currently constrained, and the supply shortage is affecting industry, including production levels at gold and platinum mining operations.

GE to provide $500 million gas turbine equipment to Saudi plants. GE Energy has signed contracts totaling more than $500 million to supply gas turbines and generators for power plant projects owned by Saudi Electricity Co. (SEC).

In the first agreement, GE Energy received a contract to supply gas turbine generators for the 960-MW expansion of the Rabigh Power Plant in Rabigh City, on the west coast of Saudi Arabia. The project is part of SEC’s initiative to provide additional power to support the region’s economic and population growth.

In addition to the Frame 7EA gas turbines at the Rabigh site, GE’s scope of supply includes Type 7A6 generators, technical advisory services during installation, and spare parts. The EPC contractor for the project is the National Contracting Co. Ltd. of Al-Khobar, Saudi Arabia.

Further expanding its presence in the Middle East’s rapidly growing power industry, GE Energy also has received a contract for gas turbines that will be used by four other power plants owned by SEC.

The GE gas turbines and generators will be manufactured at GE Energy’s facilities in Greenville, S.C., and Schenectady, N.Y., respectively.

Saudi Arabia is one of GE’s key growth regions. GE maintains a workforce of more than 600 employees in the Kingdom and has offices in Jeddah, Riyadh, and the Eastern Province, as well as joint ventures in the fields of energy, healthcare, and appliances.

—Compiled by Sonal Patel.