How Moisture-Cure Polyurethane Adhesives Are Quietly Revolutionizing High-Stress Industrial Bonding Applications

Moisture-cure polyurethane adhesives are transforming industrial bonding by offering flexibility, durability, and sustainability in extreme conditions.

NEWARK, DE, UNITED STATES, April 30, 2025 /EINPresswire.com/ -- 𝐈𝐧𝐭𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧: 𝐀 𝐌𝐚𝐫𝐤𝐞𝐭 𝐰𝐢𝐭𝐡 𝐒𝐭𝐢𝐜𝐤𝐲 𝐏𝐨𝐭𝐞𝐧𝐭𝐢𝐚𝐥

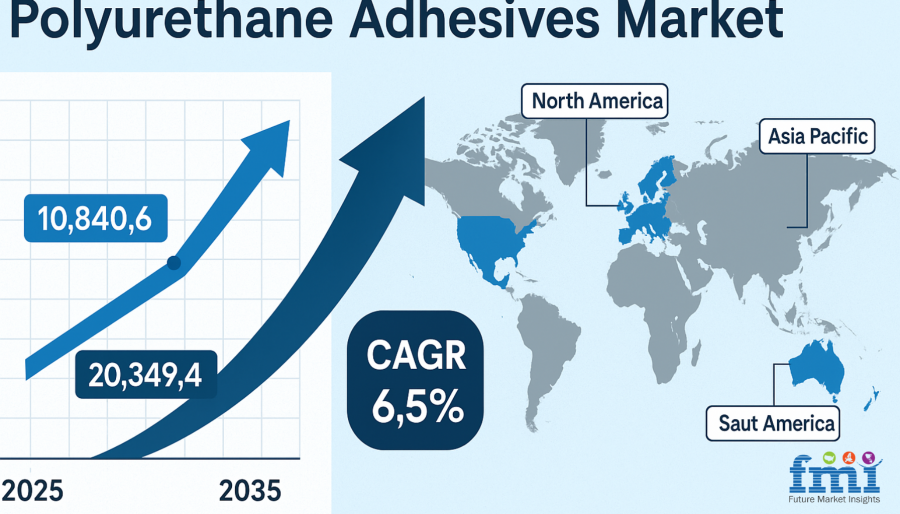

The global polyurethane adhesives market is experiencing significant traction, valued at over USD 8 billion in 2024 and expected to grow steadily through 2035. While common applications in automotive assembly, woodworking, and flexible packaging dominate industry discussions, a quieter, more transformative shift is taking place in high-stress industrial sectors. Within this evolution, one niche category—moisture-cure polyurethane adhesives—is emerging as a preferred solution in environments where traditional adhesives often underperform. Despite this, they remain underrepresented in both market analysis and public discourse.

𝐌𝐨𝐢𝐬𝐭𝐮𝐫𝐞-𝐂𝐮𝐫𝐞 𝐏𝐨𝐥𝐲𝐮𝐫𝐞𝐭𝐡𝐚𝐧𝐞 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬: 𝐀 𝐒𝐢𝐥𝐞𝐧𝐭 𝐏𝐞𝐫𝐟𝐨𝐫𝐦𝐞𝐫

Moisture-cure polyurethane adhesives, often referred to as single-component PU adhesives, cure by reacting with ambient humidity. This mechanism eliminates the need for pre-mixing or external catalysts, reducing complexity during application. Unlike traditional two-part systems that require precise ratios and limited working times, moisture-cure adhesives provide greater flexibility and ease of use in dynamic industrial environments.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/report-sample#5245502d47422d32323833

These adhesives exhibit exceptional performance in extreme conditions, such as high humidity, intense heat, and chemical exposure, making them ideal for sectors where adhesive failure is not an option. In particular, their elongation capabilities and resistance to thermal cycling give them a distinct advantage over epoxies and acrylics, which tend to become brittle under similar stresses.

𝐓𝐡𝐞 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐄𝐝𝐠𝐞: 𝐏𝐞𝐫𝐟𝐨𝐫𝐦𝐚𝐧𝐜𝐞 𝐖𝐡𝐞𝐫𝐞 𝐎𝐭𝐡𝐞𝐫 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬 𝐅𝐚𝐢𝐥

In heavy-duty sectors like mining, renewable energy, and transportation infrastructure, substrates are subjected to constant movement, vibration, and environmental stressors. Traditional adhesives such as solvent-based epoxies or hot-melts often crack or delaminate under such conditions. In contrast, moisture-cure polyurethane adhesives form highly elastic bonds capable of absorbing shock and maintaining adhesion over time.

A compelling example lies in the offshore wind energy industry, where polyurethane adhesives are increasingly used to bond structural components of wind turbine blades. These blades must endure wind shear, saline air, and UV exposure—conditions under which conventional adhesives can degrade. Moisture-cure PU adhesives, however, retain both strength and flexibility, ensuring long-term reliability.

Similarly, in underground mining equipment, metal-to-rubber bonding is critical. Moisture-cure polyurethanes, known for their ability to bond dissimilar materials, are used to affix rubber liners to steel components, reducing wear and vibration damage. In such applications, failure isn't just inconvenient—it can lead to substantial operational downtime and financial loss.

𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐂𝐨𝐦𝐩𝐚𝐭𝐢𝐛𝐢𝐥𝐢𝐭𝐲: 𝐓𝐡𝐞 𝐁𝐨𝐧𝐝𝐢𝐧𝐠 𝐨𝐟 𝐃𝐢𝐬𝐬𝐢𝐦𝐢𝐥𝐚𝐫 𝐖𝐨𝐫𝐥𝐝𝐬

A major strength of moisture-cure PU adhesives is their ability to bond dissimilar materials without compromising structural integrity. Industries increasingly rely on hybrid components—metal to composite, plastic to rubber, or glass to metal—especially in efforts to reduce weight while increasing durability.

For instance, in the rail industry, composite panels are replacing heavier steel sections to improve fuel efficiency. Moisture-cure polyurethane adhesives provide the elasticity needed to accommodate differential thermal expansion between these materials, something rigid adhesives like epoxy cannot handle without risk of fracture.

The automotive sector also benefits from this versatility. In electric vehicle (EV) battery assemblies, where lightweight materials and thermal regulation are critical, these adhesives serve dual functions—securing components and insulating against heat. Their long open time and rapid curing upon exposure to humidity allow for both manual and automated assembly processes, enhancing manufacturing efficiency.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/polyurethane-adhesives-market

𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐌𝐞𝐞𝐭𝐬 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲: 𝐓𝐡𝐞 𝐍𝐞𝐱𝐭 𝐅𝐫𝐨𝐧𝐭𝐢𝐞𝐫

Environmental considerations are increasingly shaping adhesive selection. While polyurethane chemistry has traditionally relied on petrochemical inputs and solvents, recent innovations are making moisture-cure PU adhesives more sustainable. Several manufacturers have introduced bio-based polyols into their formulations, derived from soy or castor oil, reducing dependency on fossil fuels.

Another development involves low-VOC (volatile organic compound) and isocyanate-free variants, addressing regulatory concerns, especially in European and North American markets. These adhesives are designed to maintain industrial performance while minimizing emissions, aligning with stricter workplace safety and environmental standards.

Companies like Henkel and Sika have announced next-generation moisture-cure PU adhesives for industrial use that meet LEED certification criteria and other green building standards. In infrastructure projects such as bridge retrofits or tunnel sealing, these environmentally friendly formulations are now being specified by governments and large contractors aiming for sustainable construction.

𝐑𝐞𝐭𝐡𝐢𝐧𝐤𝐢𝐧𝐠 𝐭𝐡𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐏𝐨𝐭𝐞𝐧𝐭𝐢𝐚𝐥

Despite their technical and commercial potential, moisture-cure polyurethane adhesives remain a relatively underrepresented segment in most polyurethane adhesive market reports. Their contribution to the performance, longevity, and sustainability of industrial applications is often overshadowed by broader categories such as automotive body adhesives or footwear bonding.

Yet, as industries demand more resilient, flexible, and environmentally responsible bonding solutions, the spotlight is gradually shifting toward these adhesives. Their ability to perform under stress, bond diverse materials, and meet evolving sustainability benchmarks positions them not as a niche product, but as a core enabler of next-generation industrial manufacturing.

Understanding this silent revolution calls for a more nuanced approach to market analysis—one that recognizes the unique capabilities of moisture-cure polyurethane adhesives and their growing relevance across sectors not typically associated with adhesive innovation. Future growth will likely hinge on both technical advancements and broader market awareness, making it imperative for stakeholders to monitor this evolving landscape more closely.

𝐂𝐨𝐚𝐭𝐢𝐧𝐠𝐬, 𝐈𝐧𝐤𝐬, 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬 & 𝐒𝐞𝐚𝐥𝐚𝐧𝐭𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/coatings-inks-adhesives-and-sealants

𝐏𝐨𝐥𝐲𝐮𝐫𝐞𝐭𝐡𝐚𝐧𝐞 (𝐏𝐔) 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬 𝐌𝐚𝐫𝐤𝐞𝐭 𝐛𝐲 𝐂𝐚𝐭𝐞𝐠𝐨𝐫𝐲

By Product Type:

- Thermoset

- Thermoplastic

By Technology:

- Solvent-borne

- Dispersion

- Hot-melt

- Reactive

- Others

By Applications:

- Footwear

- Automotive

- Building & Construction

- Packaging

- Electrical & Electronics

- Furniture

- Others

By Region:

- North America

- Latin America

- Europe

- South Asia

- East Asia

- Middle East & Africa

- Oceania

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries. Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release